Rotary information

It s very important to follow the instructions provided with your engine as it will cover all problems you may encounter.

Cleaning of the inlet is important so no caron deposits enter the new engine.

Checking the coils are working properly so the excess unburnt fuel doesn’t remove the protective oil layer inside the engine. It is advised to fit new coils with your new engine. Always use genuine coils.

Checking the catalytic converter is not broken apart will ensure free flowing exhaust. A blocked exhaust will cause back pressure slowing the engine, excess heat that will melt the exhaust ports in the engine and destroy the new seals very quickly.

Checking the oil is clean after your first starting of the engine will make sure all copper deposits from the previous engine are removed. Even a small amount of copper debris will quickly destroy the new bearings in the engine.

Cleaning out the oil lines from the OMP will ensure the protective oil is reaching the engine. A lot of failed engines can be traced down to this very problem.

Do not pre-mix with your fuel until after the run-in period.

Do not bump start the engine. Spinning the engine faster than the starter motor will produce very high compression and could damage the engine. New starter motors should spin at about 350-500 rpm.

On your first journey you may experience hot starts. This will clear up very quickly.

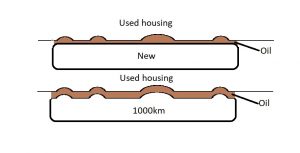

On a freshly rebuilt engine the compression will be low for a short period of time as the seals bed in to the rotor housings but it may take up to 5000km for the engine to reach its potential. Here is a diagram on a microscopic level.

Warranty and information

Here is the warranty information for all our engines.

Within run in period (500 miles 1000km)- – Do not exceed 4000 rpm. • The Oil & Oil filter must be changed again at 1000km. Only a qualified mechanic must complete the work at a registered garage. During and after your engine rebuild- it is recommended that 10/40 Mineral Oil should be used (Recommended brand Carlube). – Any involvement in any kind of accident – Any involvement in track days, Rallies or related activities will void the warranty. – Oil & Coolant must be checked regularly . – The vehicle must be serviced once a year or not exceeding 5000 miles. – The engine must never be run low on oil or coolant (oil ¾ on dipstick, coolant below L mark).

– We only cover the engine build (engine block) electrical items are not covered. – Engine failure due to lose of engine fluids are not covered (perished pipe work). – All recovery costs shall be covered by the owner of said vehicle in all incidents. In the unlikely event an engine fails we must have the engine or car returned to us for inspection before a warranty claim will be issued – All vehicle warning lights or issues must be reported via email at the earliest opportunity. – No repair or any sort of work shall be carried out to the engine in anyway unless pre approved via email to Rotorshop. – Vehicles shall not be push/bump started. – Under no circumstances shall the vehicle be road towed (always low loaded).

You may return the engine at any point if you feel unhappy with anything but it must be returned to us for inspection.

Each engine is marked with a number corresponding to each customer. If in the unlikely event the engine fails we must inspect to discover the cause of the problem. This will provide us with the information to possibly improve on our services or recommend new procedures in installing the engines. Once we have the engine returned and inspected a warranty claim can be issued and a replacement engine dispatched.